WCTI Technology Review

Technical Review Paper

Issue 12/01/2104

RE: Evaluation of Water Conservation Technology International (WCTI), Patent, Marketing Literature, and Technology Claims

A substantial amount of marketing/sales material and WEB (www.water-cti.com) site content shows that WCTI currently markets a “technology” for cooling tower water treatment based on cation softening of the makeup water. Marketing claims are made that the technology eliminates cooling tower blowdown and use of manufactured chemicals. Several patentsi are cited in their marketing and sales literature as the basis for this technology.

The current marketing and sales effort is distributor based with WCTI providing a license to distributors who are then required to use WCTI supplied water softeners, pay a royalty fee per customer, and provide routine customer service. Other than the noted WEB site, all marketing and sales activity is apparently being undertaken by the distributors via direct sales efforts and their own WEB sites such as www.h2oside.com, www.sio2tech.com and www.whitewaterco.com. In addition to the licensed distributors, WCTI is also reported to have s a number of sales “agents”, which have a primary duty to expand the network of licensed distributors and market the technology on a nationwide basis.

Several WCTI distributors are stating several obvious falsehoods in their literature, on their WEB sites, and in letters to potential customers as follows.

- Dan Duke, the principal of WCTI, was the “first” chemist to utilize softened makeup water and operate cooling towers at higher cycles of concentration. The record clearly shows that many other people have utilized softened makeup water years before Mr. Duke. For instance, Brockway Glass Company started use of softened makeup water in 1984, documented in a R&D report dated December, 1984. A total of six (6) Brockway manufacturing facilities were converted to softened makeup water by 1986.

- WCTI has patents that enable them to file patent infringement law suits against anyone using softened makeup water without a license from WCTI. Nonsense, use of softened makeup water in cooling tower is an established prior art, no one can be sued for patent infringement from simply using softened makeup water. The various WCTI patents have extremely restricted claims as to the specific conditions of use and these would have to be practiced exactly before an infringement would occur. In any event, there is significant professional opinion that the WCTI patents would be invalidated if challenged as they teach no new art.

- WCTI distributors have claimed that the softened makeup water patents held by ProChemTech (PCT), #7,595,000 and #8,128,841, infringe upon the various WCTI patents. WCTI filed an ex-parte action at the US Patent and Trademark Office (PTO) against PCT patent #7,595,000 in 2010. The PTO in a decision dated August 14, 2012, upheld the PCT patent and actually granted an additional new 12 claims, including two claims on use of softened water with hardness less than 10 mg/l.

- WCTI distributors claim that other firms, such as PCT, are simply infringing on WCTI technology. This is simply not true as proved by the PTO determination that the challenged PCT patent has unique technology. Simply put, PCT technology utilizes specific chemical inhibitor products to control the extreme corrosivity of softened water and sidestream filtration, when operations exceed eight (8) to ten (10) cycles of concentration. In contrast, WCTI claims that no corrosion control chemistry is needed and does not address deposition from airborne solids accumulating in highly cycled cooling water. In most makeup waters, WCTI is simply wrong on their claim that no corrosion inhibitor is needed when operating with softened makeup water. The first use of softened makeup water at Brockway Glass resulted in severe corrosion damage to a 1250 hp compressor; this corrosion problem has been documented several times in the past 5 years.

- WCTI distributors have claimed that firms infringing on WCTI are simple, small firms with no technical capacity. We would simply refer the reader to the PCT WEB site, www.prochemtech.com, to compare the technical content there to that of WCTI and its various distributors.

Patent Claims

Review of the cited patents shows that the WCTI technology makes the following specific claims:

- All makeup water to the cooling tower must be 100% cation exchange softened.

- Soluble silica, as SiO2, must exceed 200 mg/l in the concentrated cooling water, such concentration ideally obtained by operation of the cooling tower with no blowdown.

- If the noted concentration of silica cannot be obtained by increased cycles of concentration in the cooling tower, sodium silicate is to be added to the cooling water.

- The pH of the concentrated cooling water must exceed 9.0, such pH value ideally obtained by operation of the cooling tower with no blowdown.

- If the noted pH value cannot be obtained by increased cycles of concentration, in the cooling tower, sodium hydroxide is to be added.

- Operation of cooling towers with the above specified claims provides for inhibition of steel, aluminum, zinc, galvanized steel, stainless steel, and copper alloy corrosion.

- Operation of cooling towers with the above specified claims provides for control of silica, or silicate, scale formation in the cooling water system.

While a total of six (6) patents have been issued to WCTI, they are all rather similar in that the above claims are made with some other parameters, such as maximum conductivity, use of azole corrosion inhibitor, or the presence of metallic surfaces in contact with the cooling water, being the primary differences.

Marketing Claims

Review of the marketing claims for WCTI technology shows numerous problems when evaluated against accepted chemical principals and the reality of cooling tower operations as follows.

Claim – The patent claims that WCTI technology inhibits corrosion of steel, aluminum, zinc, galvanized steel, stainless steel, and copper alloys while the marketing literature reviewed states it “Eliminates corrosion”.

While it is generally accepted in the water management industryii that operation with pH values above 9.0 reduces the corrosion rate of ferrous metals, corrosion of aluminum, brass (dezincification), copper, and zinc (white rust) is accelerated. It is noteworthy that silicate, recommended as an additive in some cases by WCTI, is a specific inhibitor for ferrous and copper corrosion. White rust is a particular problem at pH levels above 8.2 and can only be controlled by addition of specific organic filming inhibitors.

Claim – Cycles of concentration (COC) are not limited with WCTI technology. Operation at COC values exceeding 200 are obtainable.

This appears to be pure marketing hype as cooling towers generally will go to a maximum COC between 12 and 50 due to windage (drift) loss from the unit, which is dependent upon its design, flow rate, operating load, and physical repair condition. The referenced Betz handbook shows that windage is commonly in the range of 0.2 to 0.02% of the cooling tower recirculation rate. Some simple calculations will show the maximum COC obtainable in any cooling tower due to windage loss.

Claim – “Improved results – cleaner surfaces”.

The WCTI technology totally ignores deposition on heat transfer surfaces. It is common knowledge that cooling towers are excellent air scrubbers and that much of the debris removed from the air stream is insoluble.

Any cooling system operating at high COC must have both dispersants to suspend debris and some means for its removal from the system, typically blowdown and/or filtration. A recent patentiii clearly spells out this requirement.

Claim – Silica is a corrosion inhibitor.

Silica (SiO2 – common beach sand!) as typically found dissolved at various levels in natural waters is a non-reactive substance and thus cannot function as a corrosion inhibitoriv. In contrast, the monomeric silicate anion (SiO3) is a very effective, proven corrosion inhibitor. If silica was an effective corrosion inhibitor, we could just add beach sand to our water systems as a low cost corrosion inhibitor.

Some WCTI – distributor literature reviewed addresses this chemical problem by claiming that at the higher pH values obtained by increased COC, 9.5 to 10.0, the silica present in the cooling water “polymerizes” to a reactive silicate. Given the manufacturing conditions utilized to make silicatesv, where sodium carbonate and silica are melted at high temperatures (>2000 F) to form sodium polysilicates, it is highly unlikely that there is any significant formation of silicate anion under the much less severe conditions obtained in a highly cycled cooling tower. Note that the monomeric silicates effective for control of corrosion are formed in water when the polysilicates formed under high temperature, extremely alkaline conditions hydrolyze in diluted water solution.

Claim – High pH and alkalinity obtained by high COC operation is biostatic and thus no biocides are required.

This is partly true in that biological growth is impaired, “biostatic”, at pH values above

9.0. However, impaired does not mean eliminated and use of a biocide is required to control biological growth within the cooling system. Note should be made that CTI, AWT, OSHA, and CDC only recognize oxidizing biocides as being effective against Legionella bacteria and the best oxidizing biocide at high pH is bromine.

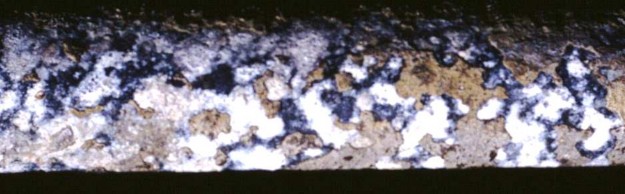

Algae growth on cooling tower fill with no biocide

In a memo provided to members of the Association of Water Technologies, Cooling Water Committee, Dr. Kati Rossmoore, Laboratory Manager, Biosan Laboratories, noted in answer to a question concerning WCTI claims that high pH in highly cycled softened makeup cooling towers control biological growth replied. “In mixed bacterial populations one species can contribute to the survival and/or growth to other species via producing metabolic by products that lower or increase the pH of the growth environment. For example, metal working fluids have usually a high pH range (pH> 9.5) and mixed bacteria communities can grow as high number as 108 or 109 cfu/ml. The simple answer to the question is that pH 9.5 or even pH > 9.5 is neither a biocide nor a preservative. Consequently bacteria can survive, multiply and grow in systems (cooling towers, metalworking fluids, etc.) having pH 9.5 or even higher.”

Claim – Testimonials are presented as to the efficacy of the WCTI technology; such as Boeing Company and Microsoft.

Testimonials lacking technical data are always suspect as to the real reason for the results claimed. In the case of both Boeing and Microsoft, their makeup water quality is known to be low in alkalinity and silica content, as well as corrosive ions such as chloride and sulfate. Given these factors, sodium silicate addition, which hydrolyzes to silicate anion on water dilution, is likely to be practiced at these locations based on the WCTI patent claims and such addition could easily account for the claimed results. Thus a program using softened, high quality (low chloride and sulfate) makeup with simple addition of sodium silicate would provide an acceptable program and totally account for the claims made. It should also be noted that the Seattle area is a low dust area, thus deposition would be much less of a problem than in locations such as Los Angles or Phoenix.

Claim – No chemical handling.

This again appears to be marketing hype given the clear use of sodium hydroxide, sodium silicate, and various azoles in the cited WCTI patents under specific conditions.

Technical Issues

Fluid cooler tubes operated with soft water

MU for four years, no corrosion inhibitor

It has been the direct experience of the reviewer since 1984 that operation of cooling towers with typical (chloride/sulfate ions present) softened makeup water and high cycles of concentration creates an extremely corrosive environment for most materials of construction in the absence of appropriate chemical corrosion inhibitors. Mild steel corrosion rates exceeding 10 mil/yr with zinc (white rust) corrosion rates exceeding 20 mil/yr have been observed in cooling towers operated with softened makeup water and no chemical corrosion inhibitor addition. This corrosion problem was addressed in the past by use of chromate based corrosion inhibitors, with acid pH adjustment to control white rust corrosion of galvanized components. Chromate chemistry was very effective with softened makeup water use.

Following banning of chromium based inhibitors due to environmental problems, various corrosion control products based on combinations of molybdate, zinc, phosphate, polysilicate, and organic compounds were found to provide acceptable corrosion control. Current technology, as shown in PCT patent #8,128,841vi, utilizes an economic combination of phosphates, polysilicate, and specific organic corrosion inhibitors, including one specific for control of white rust corrosion at pH values above 8.2, and can provide mild steel corrosion rates of less than 1 mil/yr with zinc corrosion rates less than 2 mil/yr.

We note in the WCTI and distributor literature a lack of corrosion coupon study data to substantiate their claimed corrosion control.

As with non-chemical devices, WCTI technology will appear to provide acceptable results at some sites with good quality, low chloride/sulfate, makeup water. Sites with typical water quality will experience increased corrosion rates when using softened makeup water and operation at higher cycles of concentration in the absence of appropriate corrosion inhibitors.

White rust, accelerated corrosion of galvanize and zinc containing components, is a well recognized problem in any cooling water system operated at a pH value above 8.2. The only effective means of controlling white rust is addition of specific organic corrosion inhibitors to the cooling water. Increasing cycles resulting in higher pH and alkalinity values only increases the rate of white rust corrosion in the absence of specific corrosion inhibitors. Note should be made that many laboratory studies have shown that silicate and/or silica content of cooling water has no effect on white rust corrosion rates.

WCTI ignores the deposition problem caused by airborne debris introduced into the cooling water by operation of the cooling tower. Cooling towers are very effective air scrubbers and will transfer any airborne debris into the cooling water, where it will form deposits.

For instance, a typical 1000 ton capacity cooling tower has an air flow of 290,000 cu ft per minute and can easily accumulate several inches of debris in the sump per month in the absence of blowdown and/or sidestream filtration. This issue is clearly addressed in PCT patent 7,595,000 which claims use of sidestream filtration on any cooling tower system operated at more than eight (8) cycles of concentration.

In the absence of environmental restrictions, there are no good reasons to operate a cooling tower with zero blowdown, or for that matter, at more than ten (10) cycles of concentration. The reduction in makeup water use and blowdown are really minimal past eight (8) cycles of concentration as shown by the following chart for a 1000 ton thermal load system.

|

Cycles of Concentration |

Blowdown in GPD |

|

2 |

26,550 |

|

4 |

8,850 |

|

6 |

5,310 |

|

8 |

3,793 |

|

10 |

2,950 |

Operation of cooling towers at very high cycles of concentration, or zero discharge mode, results in concentration of dissolved solids in the cooling water to levels of 10,000 to over 50,000 mg/l. The windage (drift) from such a cooling tower can present a significant problem as it is very alkaline, high pH, and can damage such things as automobile finishes, adjacent buildings, accelerate corrosion of various metal items, and kill or damage landscape plantings. It has been the experience of the reviewer that cooling water dissolved solids should be held to a maximum of 12,000 mg/l to minimize such effects.

Review Prepared by: Timothy Keister, CWT FAIC Chief Chemist

ProChemTech International, Inc.

i US Patents 6,929,749, 6,949,193, 6,998,092, 7,122,148, 7,517,493, and 7,955,553

ii Betz handbook of Industrial Water Conditioning, 9 th Edition, 1991, pages 175 to 180

iii Operation of Evaporative Cooling Towers With Minimal or No Blowdown”, US patent 7,595,000 iv “Sodium Silicate Corrosion Inhibitors: Issues of Effectiveness and Mechanism”, Report 12, PQ Corporation, Water Quality Conference, 1997

v “The Chemistry of Silica” R.K. Iler, John Wiley & Sons, NY, NY, 1979,

vi “Composition for Operation for Operation of Evaporative Cooling Towers with Minimal or No Blowdown”, US Patent 8,128,841